Preview

Intrudair s Pike opened a new category in the wingsuit series.

The PIKE is like a little Mako, strong, fast and agile, only with a smaller surface area than the Mako.

All the experience and innovations gained in Mako have been incorporated, the surface area has been reduced a bit to make a safe entry suit into the world of "high performance" suits. We have worked hard so you can reach the same speed and lift on the belly and on the back. Its power and performance allow it to fly even with Mako fleets.

After the Barracuda, the PIKE is a safe stepping stone that opens the door to the world of high performance acro suits.

Main features:

- Agile and very stable

- Mako leading edge and monochamber technology

- Redesigned form-fitting air intakes from Mako 2 (2024)

- Strong armwing pressure, power reserves and good handling

- Mako bootie technology

- Spec optimized acro-freestyle wing profile

- Large inside pockets

- Vibram® sole is sticky in all conditions, provides the best traction and grip on wet, dry, warm, and cold exits.

Test pilots/ Athlete's:

Christian Busch, Stefan Gilbert

New Leading Edge:

Thanks to the new leading edge, dense armwing ribbing and legwings tail design, the suit's performance and flare increased by at least 10-20%, this way the suit can catch up with the older, larger wing-surfaced models. Also the smoothness provides extra agility, easy handling and stability.

Intrudair specialises in full custom-made tailoring. Whether it's a skydiving suit, a tunnel suit or a wingsuit, Intrudair always makes them fully custom made. We believe that decades of custom-made tailoring experience cannot be exchanged by a proportionately zooming software. It can help but cannot replace the working experience of skilled tailors who have a massive knowledge of different body shapes and their characteristics. Our tailors have gained experience in making over 10,000 custom made garments since we started our operations. This solid base helps to form the backbone of our wingsuit sizing.

The human body structure can vary greatly from one size to another, so our colleagues cut and sew the prototypes needed for the basic measurements very carefully, this is ESSENTIAL before we launch a product. It may slow down the release of the product a little but it guarantees that we work with accurate fitting patterns.

When you receive an Intrudair wingsuit, you can be sure that our experts have checked your measurements and tailored your wingsuit to your size according to the closest fitting pattern to you. We cannot always be 100% accurate but we guarantee that when you order a custom Intrudair wingsuit, it will be made specially for you.

The shape of the wingsuits is becoming more and more streamlined in each category- see the experiments of the early 2000s (since when we talk about modern wingsuits) or the evolution of the shape of the parachute canopy.

The secret is in the details, the different profile heights and shapes determine the main flight characteristics of the suit. The most typical glide ratio and speed in each category set the direction of development.

LEADING EDGE:

Intrudair uses a special, three-layered, slightly elastic, laminated material (developed just for this purpose) for the leading edge. It keeps its shape and adapts to the position of the arm, depending on whether you use soft foam or special performance foam.

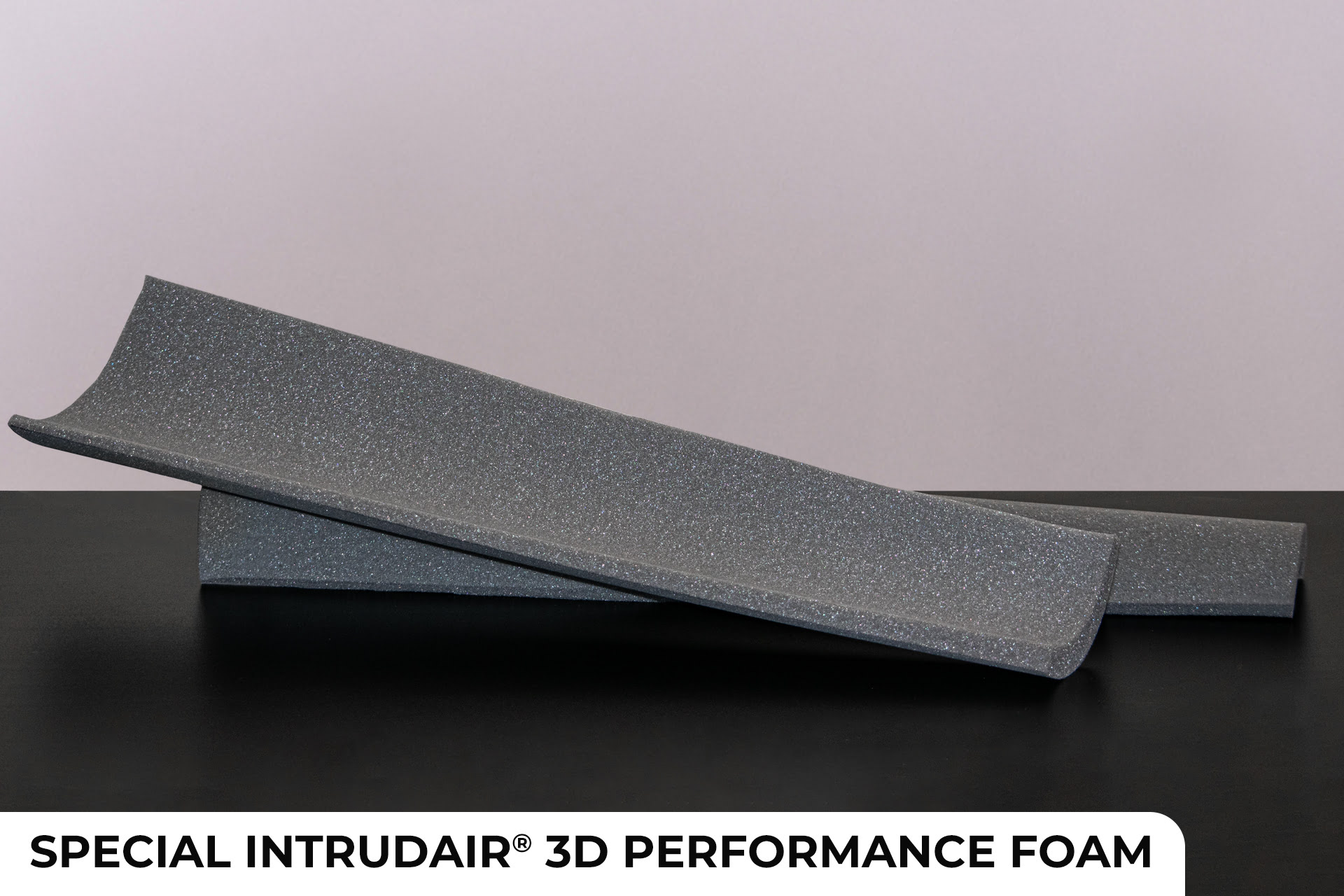

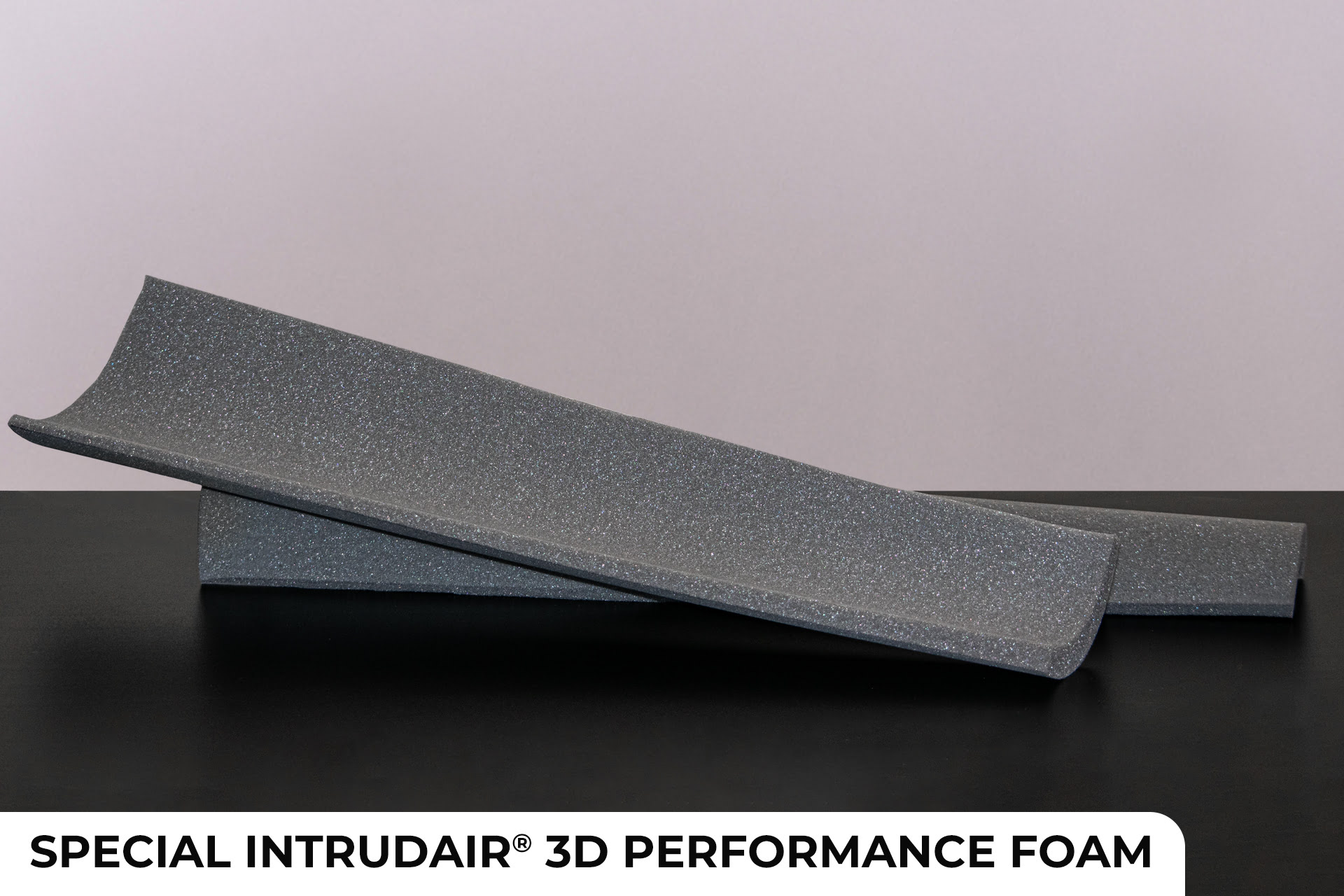

PERFORMANCE FOAM:

We use a profile-cut foam in the new Intrudair wingsuit that does not restrict free movement but holds the outside of the leading edge firmly in place while taking up and levelling the shape of your arm inside. It is easy to replace and does not break.

The amount of air entering the air intakes determines the pressure in the wings. Although this is adjustable, Intrudair puts a lot of effort into experimenting with different sizes of air intakes.

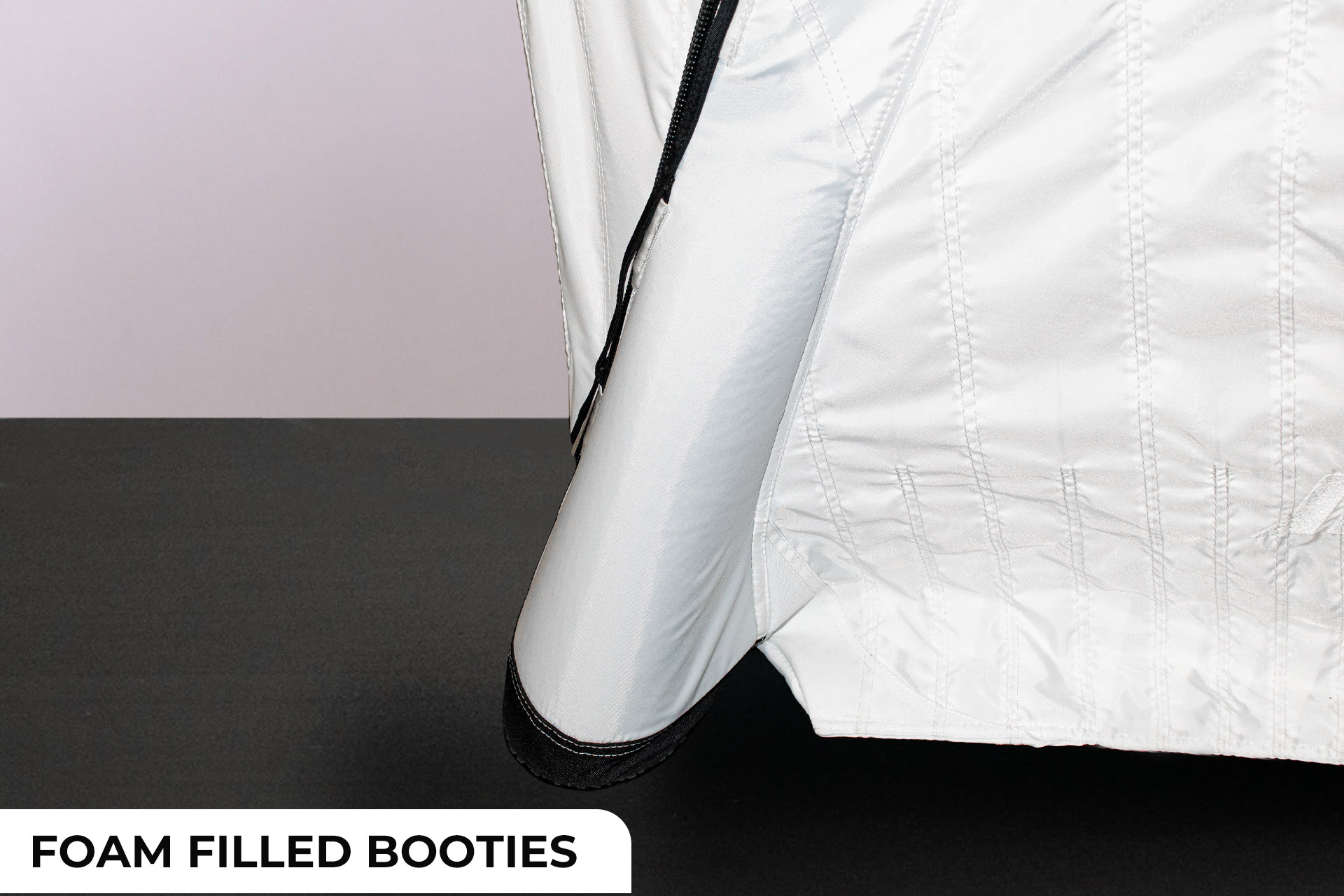

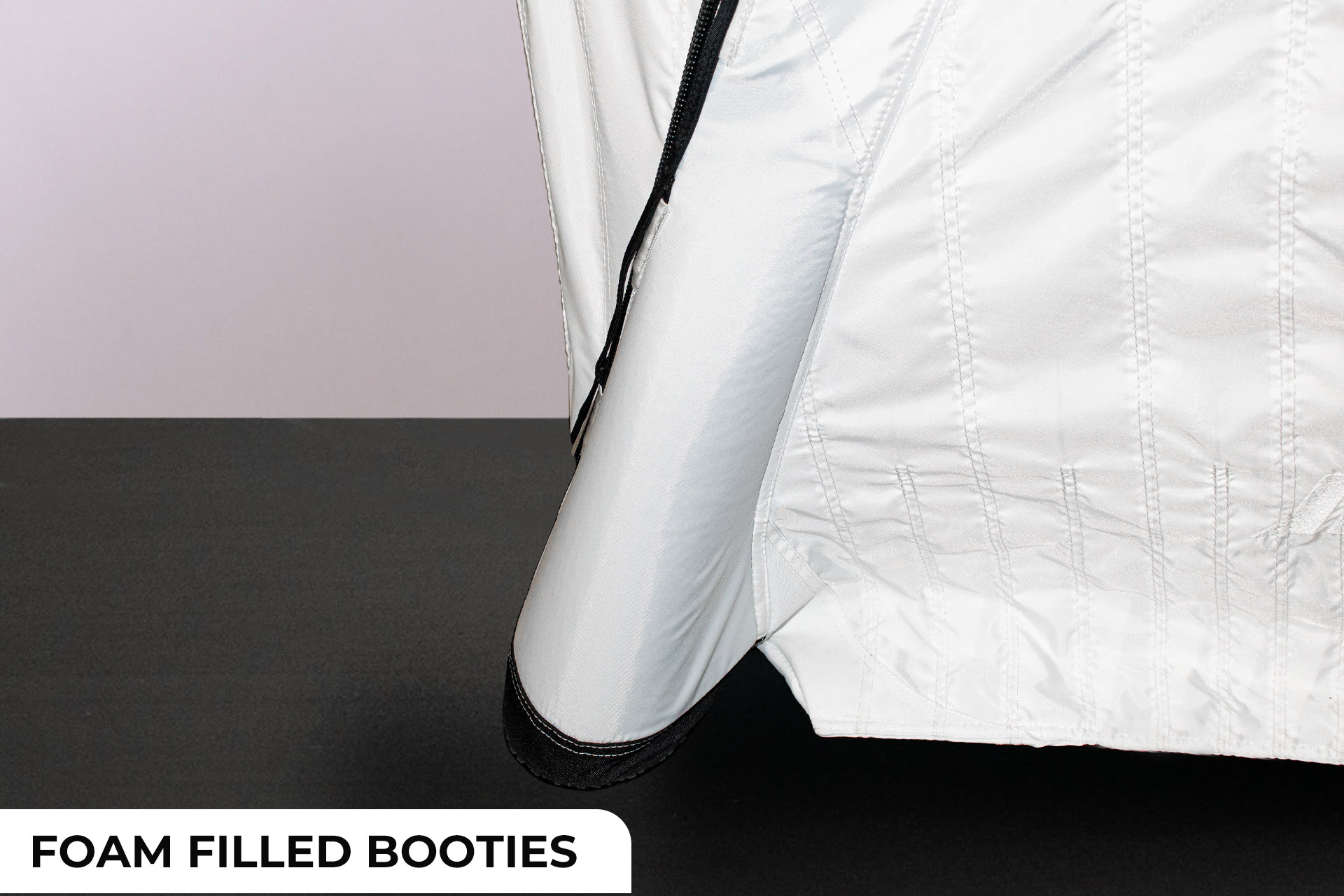

BOOTIE:

The bootie is responsible for stability. Intrudair is the only company to use a bootie-fix system developed to fix the bootie in place. This system prevents the bootie from deforming during flight. The fixed shape provides extra stability and easy manoeuvrability, and the width of the stride can be adjusted when the bootie is opened.

At the moment we believe that the well-tuned wing profile, pressure and stabilisation give the main flight parameters of our suits, which make Intrudair suits more stable and easier to fly than their competitors.

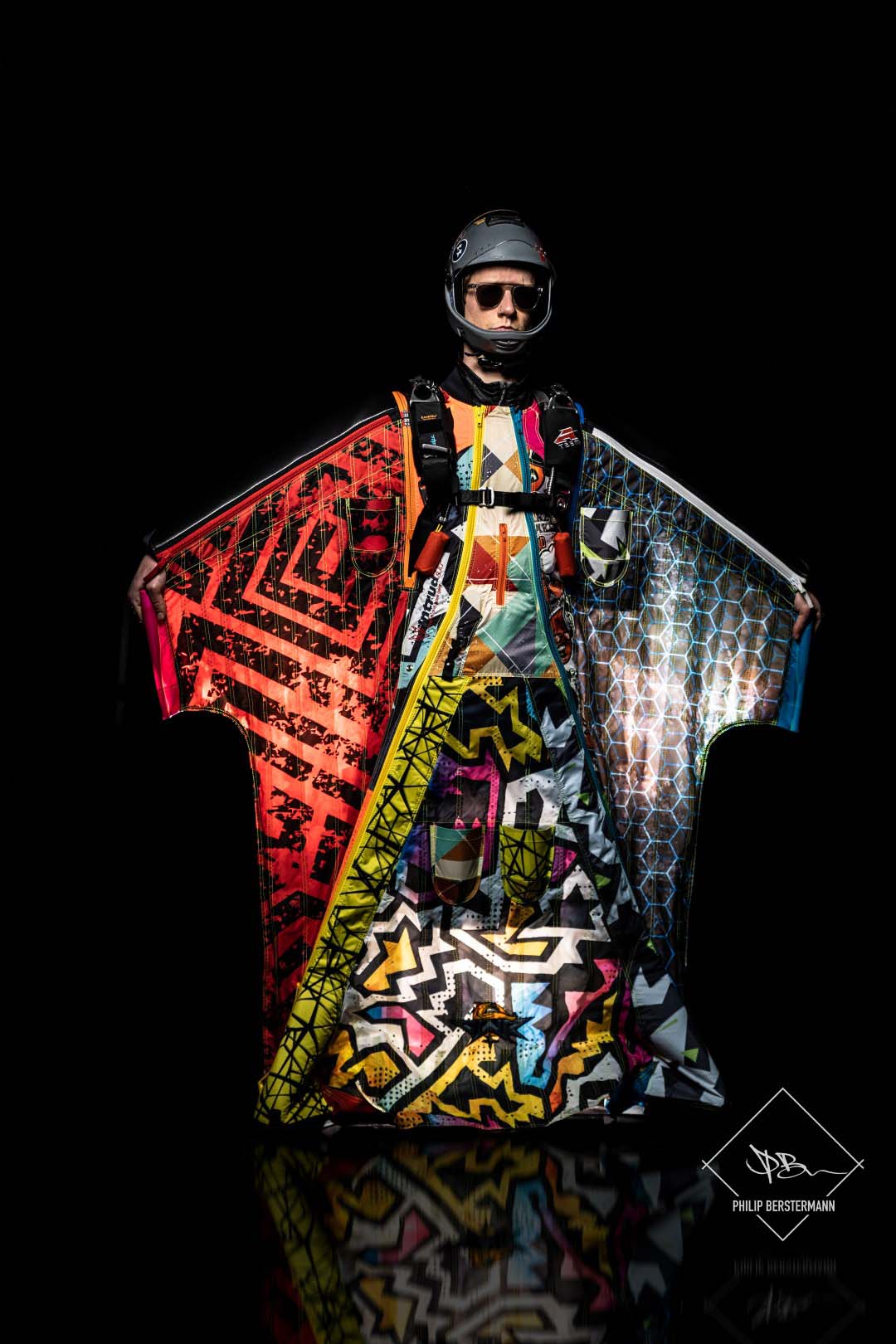

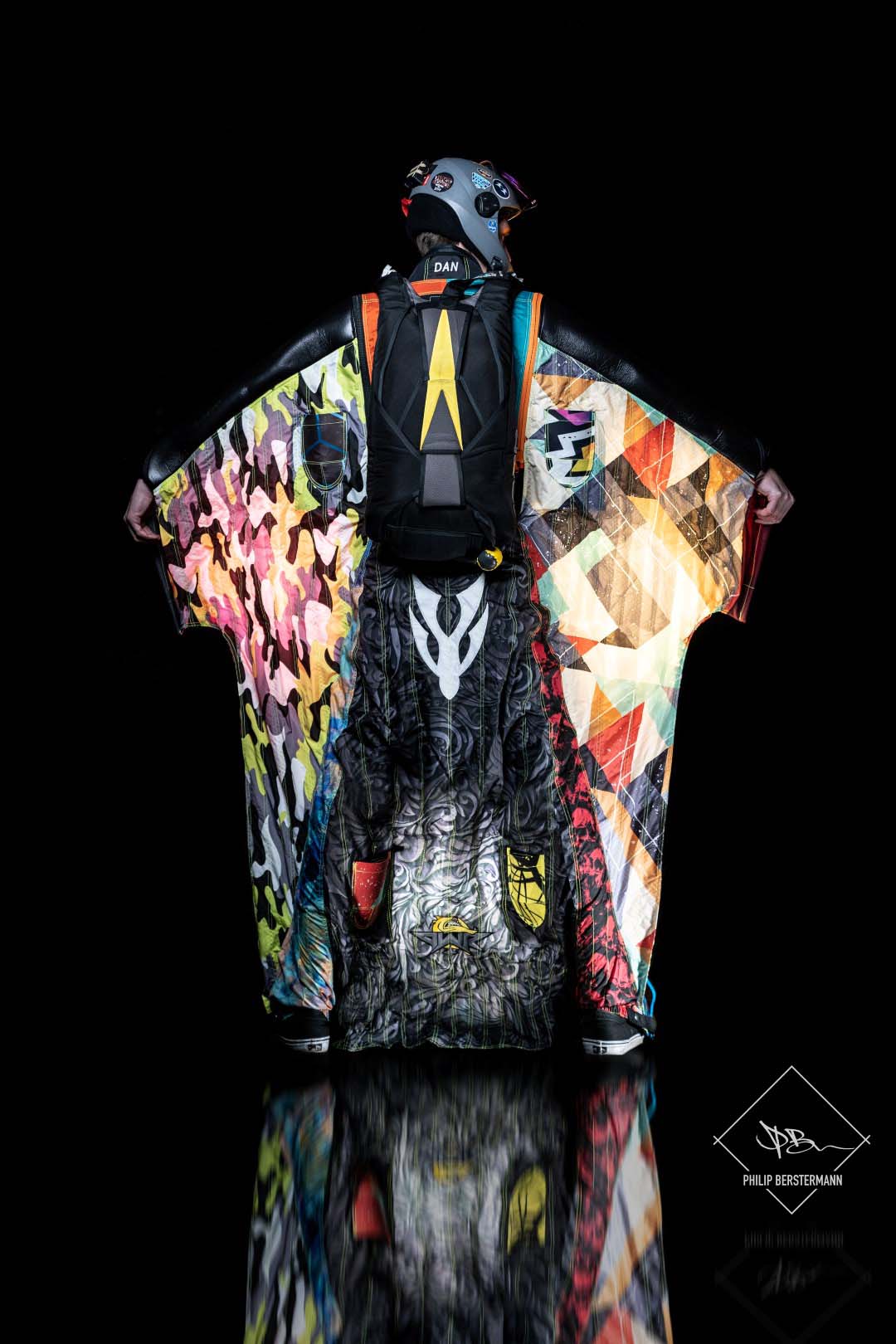

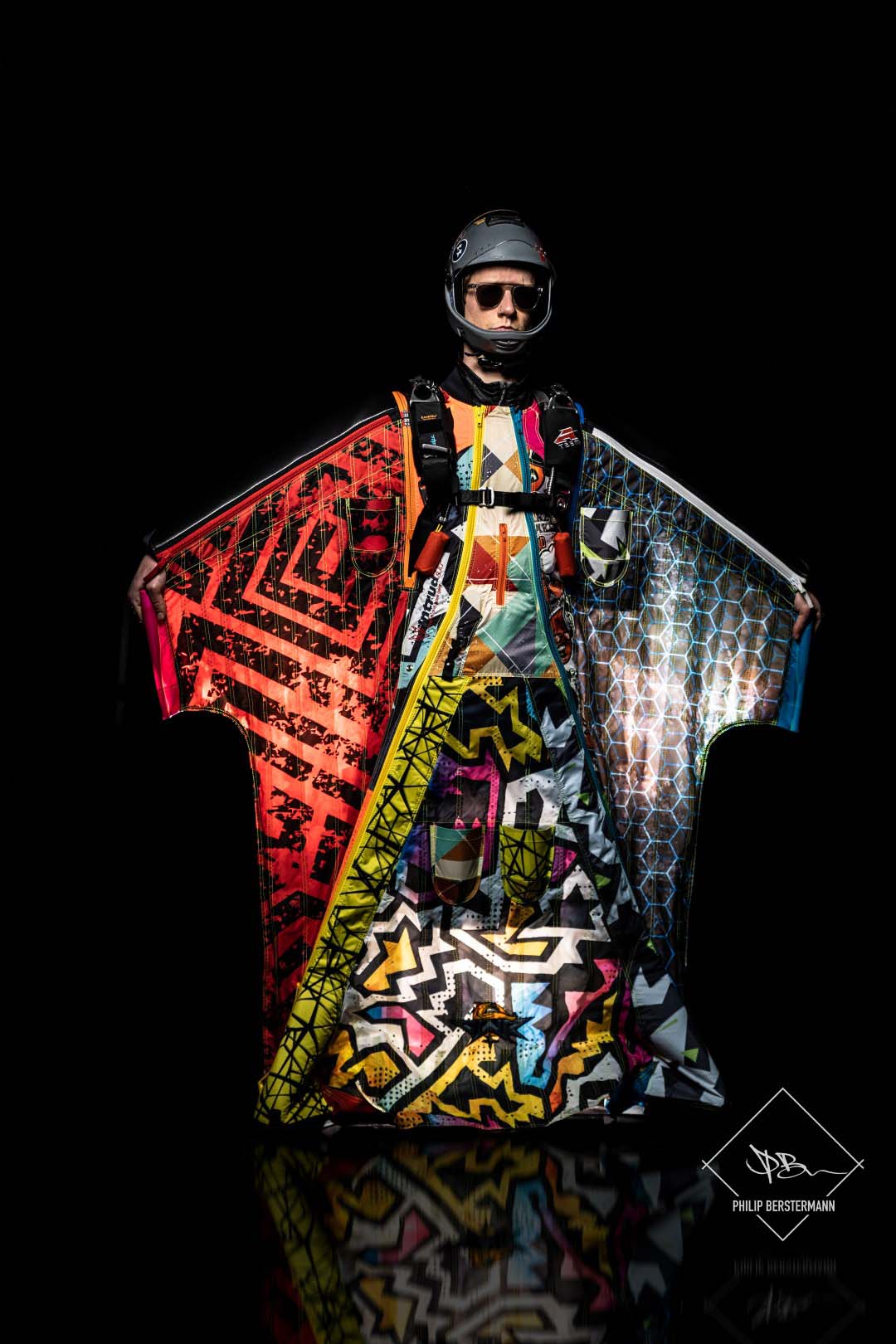

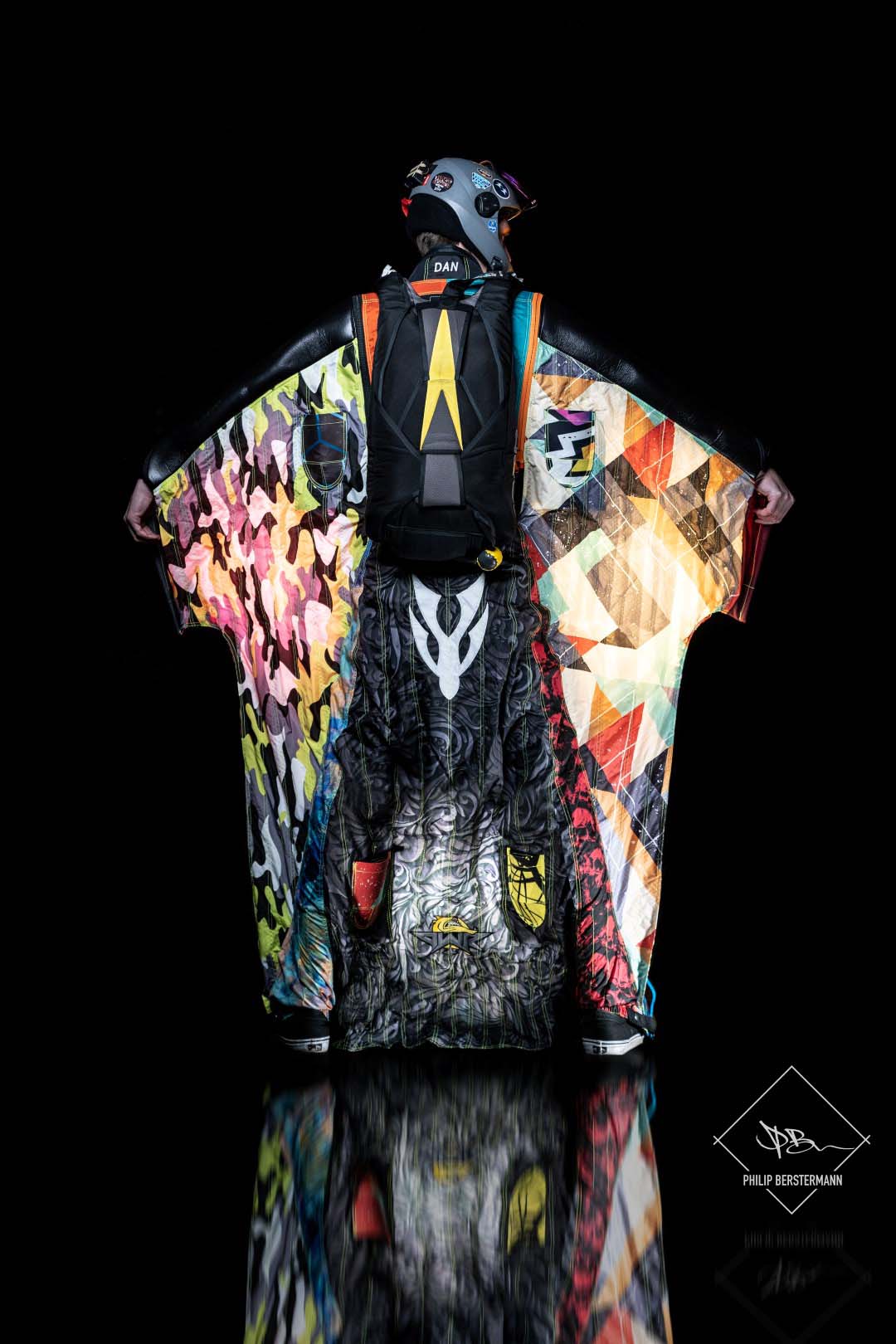

ARTWORK:

Intrudair puts a special effort into the styling of the suits, for extra custom-designed suits we offer a graphic service that crosses the boundaries of artistic suit design!Our graphic designers can create patterns on your suit that are almost unimaginable. They match and align the graphics to the over 50 printed parts of the suit. This work is very time consuming and requires full manual work, no automatic program or pattern zooming software can do this.

For normal prints the fabric is printed in rolls and cut out, for super custom prints a "blown" image is edited onto the desired design and then proofed several times before cutting. After that, thanks to the handwork of the seamstresses, almost all the patterns fit and so there are some patterns where you will only find the air vents after a long search. These all add to the length of the process but in the end you will have a truly unique, personalised and custom-designed wingsuit.

ZERO WASTE:

We pay attention to environmentally conscious manufacturing. The leftover printed materials are used in the Zero waste project so the plastics don't end up in the trash but start a new life in an extra cool customized outfit.Why is Zero waste more expensive?

Sure, the materials are leftovers but cutting the dress nearly becomes a manual operation. Each printed part is put one by one under the laser cutter in an effort to use up all the scraps, so the extra cost of printing is invested in manual labour. We use the scraps and save nature with extra working hours.

Intrudair s Pike opened a new category in the wingsuit series.

The PIKE is like a little Mako, strong, fast and agile, only with a smaller surface area than the Mako.

All the experience and innovations gained in Mako have been incorporated, the surface area has been reduced a bit to make a safe entry suit into the world of "high performance" suits. We have worked hard so you can reach the same speed and lift on the belly and on the back. Its power and performance allow it to fly even with Mako fleets.

After the Barracuda, the PIKE is a safe stepping stone that opens the door to the world of high performance acro suits.

Main features:

- Agile and very stable

- Mako leading edge and monochamber technology

- Redesigned form-fitting air intakes from Mako 2 (2024)

- Strong armwing pressure, power reserves and good handling

- Mako bootie technology

- Spec optimized acro-freestyle wing profile

- Large inside pockets

- Vibram® sole is sticky in all conditions, provides the best traction and grip on wet, dry, warm, and cold exits.

Test pilots/ Athlete's:

Christian Busch, Stefan Gilbert

New Leading Edge:

Thanks to the new leading edge, dense armwing ribbing and legwings tail design, the suit's performance and flare increased by at least 10-20%, this way the suit can catch up with the older, larger wing-surfaced models. Also the smoothness provides extra agility, easy handling and stability.

Intrudair specialises in full custom-made tailoring. Whether it's a skydiving suit, a tunnel suit or a wingsuit, Intrudair always makes them fully custom made. We believe that decades of custom-made tailoring experience cannot be exchanged by a proportionately zooming software. It can help but cannot replace the working experience of skilled tailors who have a massive knowledge of different body shapes and their characteristics. Our tailors have gained experience in making over 10,000 custom made garments since we started our operations. This solid base helps to form the backbone of our wingsuit sizing.

The human body structure can vary greatly from one size to another, so our colleagues cut and sew the prototypes needed for the basic measurements very carefully, this is ESSENTIAL before we launch a product. It may slow down the release of the product a little but it guarantees that we work with accurate fitting patterns.

When you receive an Intrudair wingsuit, you can be sure that our experts have checked your measurements and tailored your wingsuit to your size according to the closest fitting pattern to you. We cannot always be 100% accurate but we guarantee that when you order a custom Intrudair wingsuit, it will be made specially for you.

The shape of the wingsuits is becoming more and more streamlined in each category- see the experiments of the early 2000s (since when we talk about modern wingsuits) or the evolution of the shape of the parachute canopy.

The secret is in the details, the different profile heights and shapes determine the main flight characteristics of the suit. The most typical glide ratio and speed in each category set the direction of development.

LEADING EDGE:

Intrudair uses a special, three-layered, slightly elastic, laminated material (developed just for this purpose) for the leading edge. It keeps its shape and adapts to the position of the arm, depending on whether you use soft foam or special performance foam.

PERFORMANCE FOAM:

We use a profile-cut foam in the new Intrudair wingsuit that does not restrict free movement but holds the outside of the leading edge firmly in place while taking up and levelling the shape of your arm inside. It is easy to replace and does not break.

The amount of air entering the air intakes determines the pressure in the wings. Although this is adjustable, Intrudair puts a lot of effort into experimenting with different sizes of air intakes.

BOOTIE:

The bootie is responsible for stability. Intrudair is the only company to use a bootie-fix system developed to fix the bootie in place. This system prevents the bootie from deforming during flight. The fixed shape provides extra stability and easy manoeuvrability, and the width of the stride can be adjusted when the bootie is opened.

At the moment we believe that the well-tuned wing profile, pressure and stabilisation give the main flight parameters of our suits, which make Intrudair suits more stable and easier to fly than their competitors.

ARTWORK:

Intrudair puts a special effort into the styling of the suits, for extra custom-designed suits we offer a graphic service that crosses the boundaries of artistic suit design!Our graphic designers can create patterns on your suit that are almost unimaginable. They match and align the graphics to the over 50 printed parts of the suit. This work is very time consuming and requires full manual work, no automatic program or pattern zooming software can do this.

For normal prints the fabric is printed in rolls and cut out, for super custom prints a "blown" image is edited onto the desired design and then proofed several times before cutting. After that, thanks to the handwork of the seamstresses, almost all the patterns fit and so there are some patterns where you will only find the air vents after a long search. These all add to the length of the process but in the end you will have a truly unique, personalised and custom-designed wingsuit.

ZERO WASTE:

We pay attention to environmentally conscious manufacturing. The leftover printed materials are used in the Zero waste project so the plastics don't end up in the trash but start a new life in an extra cool customized outfit.Why is Zero waste more expensive?

Sure, the materials are leftovers but cutting the dress nearly becomes a manual operation. Each printed part is put one by one under the laser cutter in an effort to use up all the scraps, so the extra cost of printing is invested in manual labour. We use the scraps and save nature with extra working hours.

Configurator / Designer

CONFIGURATOR

Pre-made Designs

Only Printed

EASY-TO-SELECT DESIGNS

CONFIGURATOR

Full custom-made

Separately printable elements

ALL ELEMENTS CAN BE COLORED & PRINTED

Processing.. Please Wait!